Achieve your Lean Six Sigma Training & Certifications Today

Designed to increase your company’s competitive advantage, Six Sigma, Lean Six Sigma, and Lean are at the forefront of training for organizations that are focused on implementing needed change and improvements.

Certify for the Six Sigma Training Skills you Desire and Those That Employers Need

Lean Six Sigma Green Belt

Lean Six Sigma Black Belt

Quite simply, Six Sigma is the foremost form of methodological practices for improving customer satisfaction and improving business processes throughout an organization.

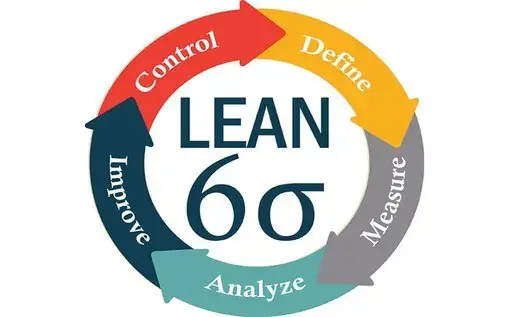

DMAIC/DMADV

Existing and New Processes

Five Whys

Break down to the Issue to the Root Cause

CTQ Tree

Critical to Quality Tree

Custom Or Blended Delivery Training

Cause of Defects

What is the difference?

It is important to begin by understanding the three main Six Sigma methodologies. Once you have gained an understanding of their differences, you can better determine which one is right for your organization.

Six Sigma

Six Sigma Lean

Lean

Mastered and implemented by Motorola Corp., Six Sigma is regarded as the gold standard in methodologies for process improvement.

The core focus of Six Sigma is to reduce variance and errors in a production process. The result is higher quality products and services. The bottom-line goal is to reduce defects to 3.4 per one million opportunities.

A true combination of the best of Six Sigma and Lean, and most often used by organizations that realized they had issues in both arenas.

Six Sigma Lean results in eliminating waste as with methods defined in Lean and garnering process improvement by implementing DMAIC and DMADV in place.

training to keep your team ahead of the technology skills curve.Similar to Six Sigma in its focus on process improvement, Lean has a driving focus on attacking and eliminating waste.

Quite simply, if an activity does not add value to the end user of the product or service it should be eliminated. In our Lean Six Sigma training, you will learn the eight key areas in which Lean seeks to eliminate waste.